Yethula isimiso somshini wokuwasha izingilazi zaselabhorethri kanye nemisebenzi eyisikhombisa yezinhlelo ezintathu ezinkulu

I-Automatic Glassware Washer iyisethi yokuhlanza okuzenzakalelayo, umsebenzi wokomisa njengomunye wemikhiqizo yobuchwepheshe obuphezulu. Ingakwazi esikhundleni sokuhlanza okubhaliwe kanye nokomisa kwe-glassware ehlukahlukene yaselabhorethri, izinhlelo ezihlukahlukene ezihlelekayo, indlela yokuhlanza ukhiye owodwa inciphisa kakhulu umthwalo ongasebenzi wabacwaningi besayensi, kuyilapho ikhulisa ukuzinza nokuvumelana kokuhlanza i-batch-to-batch, ikakhulukazi ukuhlolwa kokuvikelwa kwemvelo, i-biopharmaceuticals, ukuhlolwa kokudla nezidakamizwa nezinye izimboni.

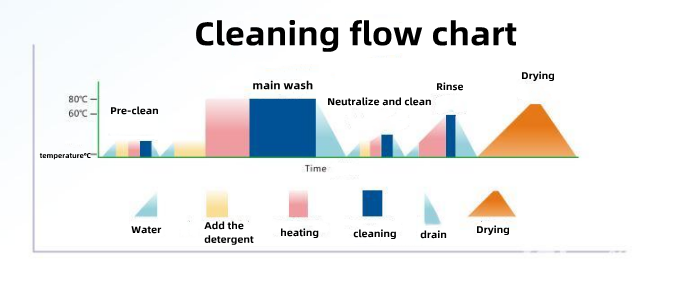

Isimiso sokusebenza se-Glassware Washer:

Ngamanzi kampompi namanzi ahlanzekile (noma amanzi athambile) njengendlela yokusebenza, usebenzisa i-ejenti ethile yokuhlanza, eqhutshwa yiphampu yokujikeleza, uketshezi lokuhlanza lugezwa ngokuqondile ku-360 ° ngaphakathi nangaphandle komkhumbi ngokuzungezisa ingalo yokufafaza kanye nepayipi yokufafaza. , ukuze ukhiphe, u-emulsify futhi uchithe izinto ezisele emkhunjini ngaphansi kwesenzo samandla emishini namakhemikhali; Ngaphezu kwalokho, uketshezi lokuhlanza lungashiswa ngokuzenzakalelayo, bese izitsha zingashiswa zihlanzwe futhi zifakwe i-disinfected ukuze kutholakale umphumela ongcono wokuhlanza. Uma imodeli enomsebenzi wokomisa ikhethiwe, ibhodlela lesampula lingaba nomoya oshisayo omisiwe ngemva kokugeza ukugwema ukungcoliswa kwesibili okubangelwa ukungasuswa ngesikhathi.

I-Laboratory Glassware Washer inokuhlanza okuzenzakalelayo nokomisa kanye neminye imisebenzi yezinqamuleli, futhi yonke inqubo yayo yokusebenza ikakhulukazi yakhiwe amasistimu amakhulu amathathu, ethulwa ngale ndlela elandelayo:

1. I-Conductivity online monitoring system

Phakathi nenqubo yokuhlanza, ngisho nezinsalela ezincane kakhulu emanzini ahlanzekile zingathinta kakhulu imiphumela yokuhlanza. Iwasha yamabhodlela isetha umsebenzi we-alamu yesistimu, uma i-conductivity kuseshini yokugcina yokuhlanza idlula inani elimisiwe lekhasimende, okokusebenza kuzowasha kabusha ngokuzenzakalelayo. Uhlelo olusha lokuqapha ukuqhutshwa kwe-inthanethi lwamahhala olusuka ewasha amabhodlela luqeda isidingo sezindleko ezengeziwe zokulungisa nokulinganisa. Uhlelo luhlanganiswe endleleni yokuhamba kwamanzi futhi alukho ukuxhumana okuqondile nesistimu yamanzi, enembile kakhulu.

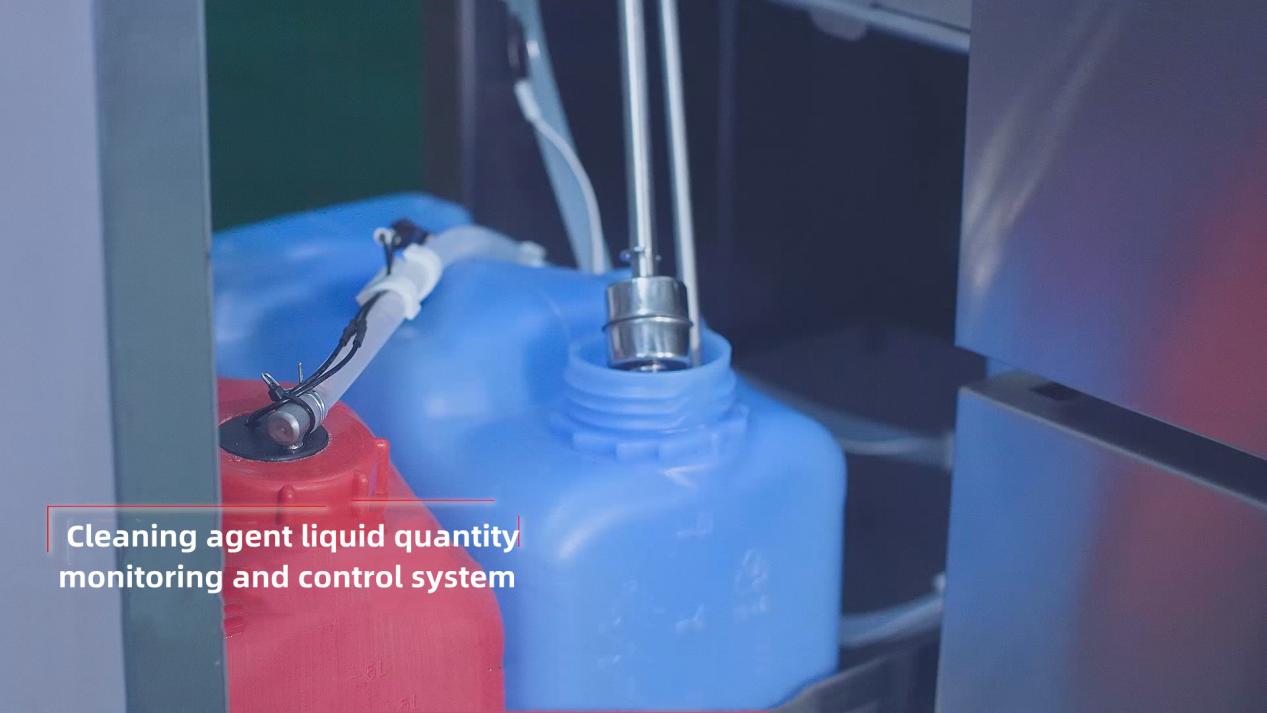

2. I-ejenti yokuhlanza i-liquid quantity monitoring and control system

I-ejenti yokuhlanza ivolumu yokuqapha umthamo we-liquid kanye nohlelo lokulawula kwandisa ukuphepha kwesistimu. Uma wengeza ikhemikhali yesihlanzi, isistimu ivikela imiphumela ye-liquid viscosity nezinga lokushisa elizungezile kuzici zokugeleza koketshezi, okuvumela ukusatshalaliswa kwevolumu yoketshezi enembe kakhudlwana. Indlela elula yokulawula i-flowmeter esetshenziswe esikhathini esidlule yayithintekile yizici zemvelo. Ubuchwepheshe obusha bewasha ibhodlela bunokunemba okukhulu nokuphepha.

3. Futha uhlelo lokulawula izinga lokugeleza kwengalo

Ngomsebenzi wokuhlanza isifutho esinengcindezi ephezulu, okungukuthi, isistimu yokulawula izinga lokugeleza kwezingalo ze-spray, i-Laboratory Washer ingakwazi ukukhomba ngokuzenzakalelayo isistimu yebhasikidi elayishiwe, futhi ilawule ngokunembile isivinini sengalo yokufafaza ekamelweni lokuhlanza. Uma ukulayisha kungalungile, iwasha yebhodlela ithola iphutha ekuqaleni kohlelo bese imisa umsebenzi. Phakathi nenqubo yokuhlanza, umshini wokuwasha amabhodlela uthola ijubane lengalo yokufafaza ukuze uqinisekise ukuthi ijubane lingaphakathi kwebanga elimisiwe, ukuze kuzuzwe umphumela ongcono wokuhlanza.

Umshini wokuwasha we-Glassware wezici zaselabhorethri:

1. Ukuphakama okuguquguqukayo ubakaki ukuze kuqinisekiswe ukuhlanzwa okuphumelelayo kwezincazelo ezahlukene zezitsha;

2. Ukulawula izinga lokushisa lamanzi kabili ukuze kuqinisekiswe izinga lokushisa lokuhlanza lamanzi;

3. Uketshezi lokuhlanza lungasethwa futhi lwengezwe ngokuzenzakalelayo;

4. Ngemuva kokuhlanza, ingamiswa ku-situ;

5. Iphampu yokujikeleza esezingeni eliphezulu engenisiwe, ingcindezi yokuhlanza ezinzile futhi enokwethenjelwa;

6. Hlela indawo yokuhlanza ngokuvumelana nesimiso se-fluid mechanics ukuqinisekisa ukuhlanzeka kwento ngayinye;

7. Ingalo yesifutho ejikelezayo yedizayini elungiselelwe yomlomo wobukhulu obuphezulu iqinisekisa ukuthi isifutho simbozwe ngaphandle kwama-engeli afile ku-360 °.

Isikhathi sokuthumela: Mar-04-2022